Product description

* ADJUST YOUR FUEL PRESSURE WITHOUT STRETCHING SPRINGS

* BULLETPROOF DESIGN ELIMINATES HAMMERED SEATS

* CURE FOR HARD STARTING AND LOW POWER

* OFV010 USE WITH STOCK FUEL SYSTEMS AND DIESEL FUEL

* LEAK PROOF CHECK VALVE PREVENTS BACK FLOW TO TANK

* PRECISE FUEL PRESSURE FOR THE BOSCH P7100 INJECTION PUMP

* VALVE IS PRESET AT FACTORY TO 30 TO 32 PSI

After 14 months of testing, Tork Teknology is releasing the world's first ADJUSTABLE over flow valve for the Cummins 12 valve, equipped with the P pump. Every single problem that has plagued the Bosch design has been SOLVED, including eroded seats and broken springs. Finally, there is a reliable P pump overflow valve that is adjustable!

Talk to any owner of a Cummins P pump, and he will tell you he has replaced his P7100 overflow valve. Several of the HP guys are on their second and third return valve. WHY? The number one complaint that I hear is "My Cummins 5.9 diesel is losing power and it's difficult to start". With that information, we cut many over flow valves in half to find out why. We were shocked by what we saw! Through 14 months of testing on a flow bench and on our test truck, we know exactly why the Cummins return valve is not a good design.

How a better spring will raise your fuel pressure

The Bosch spring has a history of breaking and it loses its spring force. This dramatically reduces the fuel pressure in your injection pump. This causes low power and your Cummins will be difficult to start. To cure this problem, we use premium, custom made springs in our overflow valves. The leading spring maker in the U.S. has worked with us to produce a superior spring. The spring manufacturer tested the service life at 1,000,000 cycles to the second power. Basically, infinite life! Our new design seat and ball puts less fatigue on the spring, as well.

The Bosch overflow valve will idle at 15 to 18 PSI. Our valve will show 25 to 26 PSI at idle. The shifter on our test truck vibrates much less and the engine idles 30 RPM faster with the Tork Tek valve. Your engine will run with less vibration and experience an off-idle power increase (great for towing). Customers email every week and say that starting is much easier! The best return valve they have ever used on their Cummins.

Why bad seats cost you fuel pressure

The other common defect in the original valve is seat erosion. Many of the Bosch overflow valves that we cut in half had rounded seats. Take a look at photo #4. The seat is supposed to be flat. It should look like a tapered cone. It's rounded from the hammering of the ball. With the seat rounded, the ball is now .050 to .075 deeper in the valve and your spring is now longer. The longer spring exerts less force on the ball. Less spring force equals less fuel pressure. That's why your valve quit working and you lost fuel pressure and power on your Cummins P pump.

The other common defect in the original valve is seat erosion. Many of the Bosch overflow valves that we cut in half had rounded seats. Take a look at photo #4. The seat is supposed to be flat. It should look like a tapered cone. It's rounded from the hammering of the ball. With the seat rounded, the ball is now .050 to .075 deeper in the valve and your spring is now longer. The longer spring exerts less force on the ball. Less spring force equals less fuel pressure. That's why your valve quit working and you lost fuel pressure and power on your Cummins P pump.

Eroded seats are the second leading cause of failed P7100 overflow valves. (We have sectioned many valves) The other bad design of the OEM valve is the lack of material supporting the seat. From the chord line where the ball touches the seat to the edge of the seat, there is only .009 (three hair thicknesses) of steel to prevent seat erosion. That is not enough material to support the ball. Over time, the ball will hammer the seat to the point where your valve will not work. Tork Teknology redesigned the Cummins return valve to eliminate failed seats. IT'S A BULLETPROOF DESIGN!

Eroded seats are the second leading cause of failed P7100 overflow valves. (We have sectioned many valves) The other bad design of the OEM valve is the lack of material supporting the seat. From the chord line where the ball touches the seat to the edge of the seat, there is only .009 (three hair thicknesses) of steel to prevent seat erosion. That is not enough material to support the ball. Over time, the ball will hammer the seat to the point where your valve will not work. Tork Teknology redesigned the Cummins return valve to eliminate failed seats. IT'S A BULLETPROOF DESIGN!

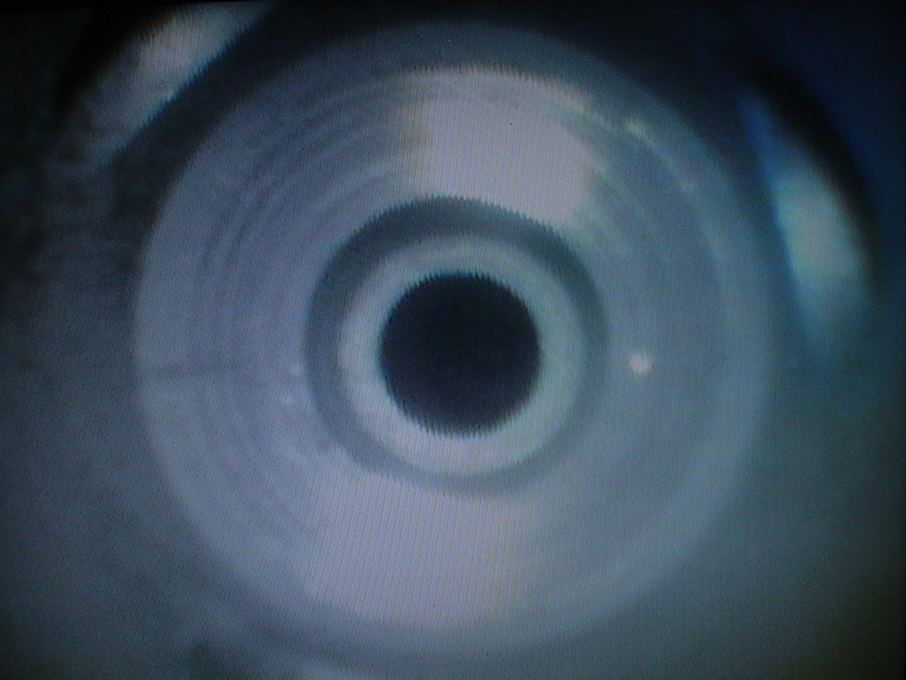

Your Cummins overflow valve leaks! Ours is leak proof

We have tested new Bosch overflow valves and most of them leak. In fact, there is a technical service bulletin stating that the Cummins valve is NOT a check valve and leakage is OK. Why would you want a valve that leaks? The Bosch P7100 overflow valve uses a machined seat, which is OK, if not subjected to heat treating. Machined seats leak after heat treat because of thermal distortion. The secret to a leak proof valve is super finishing the seat AFTER heat treat. (see photo #5) It took weeks to perfect the super finishing of the seat and the results are worth it! Our valve has zero leakage and acts as an anti-siphon check valve. The leak proof seat prevents back flow to the tank.Starting your Cummins will never be easier because your fuel system will always be in prime.

We have tested new Bosch overflow valves and most of them leak. In fact, there is a technical service bulletin stating that the Cummins valve is NOT a check valve and leakage is OK. Why would you want a valve that leaks? The Bosch P7100 overflow valve uses a machined seat, which is OK, if not subjected to heat treating. Machined seats leak after heat treat because of thermal distortion. The secret to a leak proof valve is super finishing the seat AFTER heat treat. (see photo #5) It took weeks to perfect the super finishing of the seat and the results are worth it! Our valve has zero leakage and acts as an anti-siphon check valve. The leak proof seat prevents back flow to the tank.Starting your Cummins will never be easier because your fuel system will always be in prime.

Starting your Cummins is now easier

Normally, the check valve in the Cummins lift pump would prevent back flow. Unfortunately, the lift pump check valve is not a good design. The check valve is the weak link in the Bosch lift pump. If a hose or tube develops a leak from the overflow valve to the fuel tank, fuel can flow by gravity back to the tank. This is made worse if you park on an incline. Starting the engine in the morning is next to impossible. Our design adds a secondary check valve into your Cummins fuel system and prevents back flow to the tank. Your truck will start easier with a leak proof Tork Tek overflow valve!

The Tork Tek overflow valve is adjustable! This one feature took weeks to develop. You can now adjust your fuel pressure without taking your valve apart to add shims or to stretch the spring. Simply loosen the jam nut and turn the hex plunger. This patent pending design has a range of 22 to 35 PSI. One customer purchased the valve for one reason. He said that if the spring loses a little tension in five years, he can increase the fuel pressure in minutes by adjusting the plunger.

Key to max power

Here's a tip for maximum power. Peak fuel flow on a stock system is 31 PSI. Fuel flow will fall off above 31 PSI. The Bosch P7100 lift pump is a pressure sensitive pump and pressures above 31 to 32 PSI will show less fuel flow. This has been verified with precise flow meters. Set your fuel pressure for 31 PSI for max fuel flow.

Little known secret why lift pumps are failing

The current Bosch over flow valve has a .105 inlet hole. The inlet hole size used to be .168 in diameter. Did you ever wonder why the hole size was reduced? The reason is, it protects the OEM seat and spring from damage. The small hole acts as an orifice snubber. Testing has shown that the hole diameter is too small !! The problem is, the small inlet hole has created huge pressure spikes in the fuel system and is wrecking lift pumps. The pressure spikes put a terrible load on the lift pump check valves.

The current Bosch over flow valve has a .105 inlet hole. The inlet hole size used to be .168 in diameter. Did you ever wonder why the hole size was reduced? The reason is, it protects the OEM seat and spring from damage. The small hole acts as an orifice snubber. Testing has shown that the hole diameter is too small !! The problem is, the small inlet hole has created huge pressure spikes in the fuel system and is wrecking lift pumps. The pressure spikes put a terrible load on the lift pump check valves.

The Tork Tek valve features an inlet hole size that reduces pressure spikes by 39.7%. Your lift pump will last longer because it is not subjected to the higher pressure spikes of the Bosch design. A small but critical change to the inlet hole size has a direct relationship on the life of your lift pump.

Bullet proof seat design

Our goal was to produce a valve that has superior seat life. After many tests, we discovered that the number, size and location of the outlet holes were critical to the life of the ball and seat. We engineered the new design to put minimal stress on the seat. Less stress means longer seat life. You can now run your Cummins diesel knowing you have the best overflow valve on your Bosch P7100 injection pump.

There is nothing worse than showing your buddy a new performance device on your truck and it's rusted. We don't black oxide any of our parts because it is not a rust resistant coating. Tork Tek plates all overflow valves in a two step process. The initial plating is coated with a second anti-corrosion sealant. Plating is a more expensive process, but it's worth it ! Your valve will look great and remain rust free for many years.

OFV010 Direct replacement for the Bosch overflow valve

The OFV010 is for stock fuel systems that run on diesel fuel. Do not use this valve with WVO or biodiesel. These fuels will erode the ball and wreck the seal. If you have a stock fuel system and run alternate fuels, order the OFV020. The OFV020 is built with stainless components and a Viton seal. Included with the overflow valve are banjo seal washers and detailed instructions. Installation is easy and takes only a few minutes.

The OFV010 is for stock fuel systems that run on diesel fuel. Do not use this valve with WVO or biodiesel. These fuels will erode the ball and wreck the seal. If you have a stock fuel system and run alternate fuels, order the OFV020. The OFV020 is built with stainless components and a Viton seal. Included with the overflow valve are banjo seal washers and detailed instructions. Installation is easy and takes only a few minutes.

Every Tork Teknology product is covered by a 45 day money back return policy. We guarantee 100% satisfaction with your purchase or you get your money back.

The TorkTek adjustable overflow valve is second to none. It is a direct replacement for the Cummins overflow valve and will be the last overflow valve you ever buy!

PLEASE NOTE: THE OFV010, 020 AND 030 ARE NOT TO BE USED WITH A FASS OR AIR DOG PUMP. IF YOU RUN EITHER OF THESE PUMPS, USE THE HP OVERFLOW VALVES. THE NEW DESIGN VALVE WILL GIVE YOU MUCH BETTER FUEL PRESSURE AT FULL POWER.